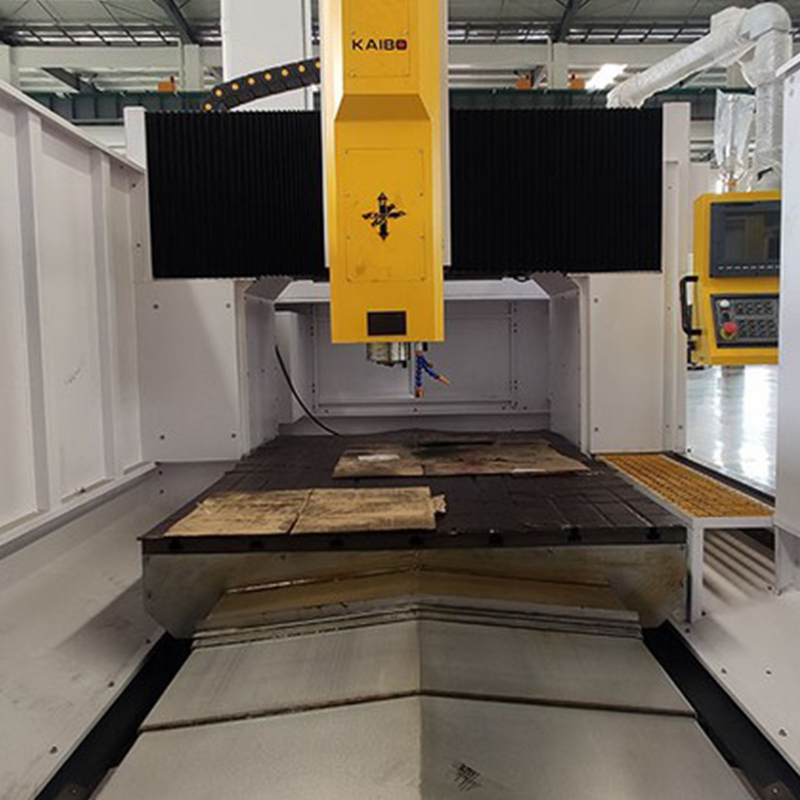

| positioning accuracy: | 0.01 mm |

|---|---|

| Repeatability: | 0.005 mm |

| working desk size: | 1300*1700mm |

|---|---|

| T-slot dimensions: | 7T-18-190 mm |

| Maximum load: | 2000 kg |

| X/Y/Z axis travel: | 1300/1700/500 mm |

|---|---|

| Gantry width: | 1360 mm |

| Beam to workbench: | 700 mm |

| Spindle nose to worktable: | 150-650 mm |

| Door opening width: | 1350 mm |

| Maximum feed speed G00: | 15 m/min |

|---|---|

| Maximum processing speed G01: | 10 m/min |

| X/Y/Z axis motor power: | 2900W/2900W/2900W |

| Spindle motor power: | 11 kilowatts |

|---|---|

| Maximum spindle speed: | 12000 rpm |

| Tool holder: | BT40 |

| Spindle diameter: | - |

| Power supply and total capacity: | 3P/380V/50Hz/30KVA |

|---|---|

| Machine weight: | 12000 kg |

| aspect: | 4520*2600*2880mm |

| Controller: | Syntec 21MA/Taiwan |

|---|---|

| AC servo motor (driver): | Yaskawa/Japan |

| Spindle inverter: | Innovation/China |

| Linear Guides: | 45 Hiwin, PMI/Taiwan |

| Ball Screw: | 5010/5010/4010 Hiwin, PMI/Taiwan |

| Electronic handwheel: | EHDW-BA5S-1 Future/Taiwan |

| Lubrication system: | YET-A2P2 ISHAN/Taiwan |

| Oil Cooler: | Parsonshal/China |

| air conditioner: | EA-6AP Parsonsall/China |

| Pneumatic system: | AirTac/Taiwan |

| Chip conveyor: | Internal thread type |

| Water tank capacity: | 323L |

| Water pump power: | 480 W |

| ATC Type: | Arm Type |

|---|---|

| Air traffic control capabilities: | 24 items |

| positioning accuracy: | 0.01 mm |

|---|---|

| Repeatability: | 0.005 mm |

| working desk size: | 1100*1300mm |

|---|---|

| T-slot dimensions: | 6T-18-185 mm |

| Maximum load: | 2000 kg |

| X/Y/Z axis travel: | 1100/1300/400 mm |

|---|---|

| Gantry width: | 1140 mm |

| Beam to workbench: | 660 mm |

| Spindle nose to worktable: | 150-550 mm |

| Door opening width: | 1170 mm |

| Maximum feed speed G00: | 15 m/min |

|---|---|

| Maximum processing speed G01: | 10 m/min |

| X/Y/Z axis motor power: | 1800W/1800W/1800W |

| Spindle motor power: | 7.5kW |

|---|---|

| Maximum spindle speed: | 12000 rpm |

| Tool holder: | BT40 |

| Spindle diameter: | - |

| Power supply and total capacity: | 3P/380V/50Hz/20KVA |

|---|---|

| Machine weight: | 7500 kg |

| aspect: | 3200*2450*2800mm |

| Controller: | Syntec 21MA/Taiwan |

|---|---|

| AC servo motor (driver): | Yaskawa/Japan |

| Spindle inverter: | Innovation/China |

| Linear Guides: | 45 Hiwin, PMI/Taiwan |

| Ball Screw: | 4010 Hiwin, PMI/Taiwan |

| Electronic handwheel: | EHDW-BA5S-1 Future/Taiwan |

| Lubrication system: | YET-A2P2 ISHAN/Taiwan |

| Oil Cooler: | Parsonshal/China |

| Pneumatic system: | AirTac/Taiwan |

| Chip conveyor: | Internal thread type |

| Water tank capacity: | 220 liters |

| Water pump power: | 400W |

| ATC Type: | Arm Type |

|---|---|

| Air traffic control capabilities: | 24 items |