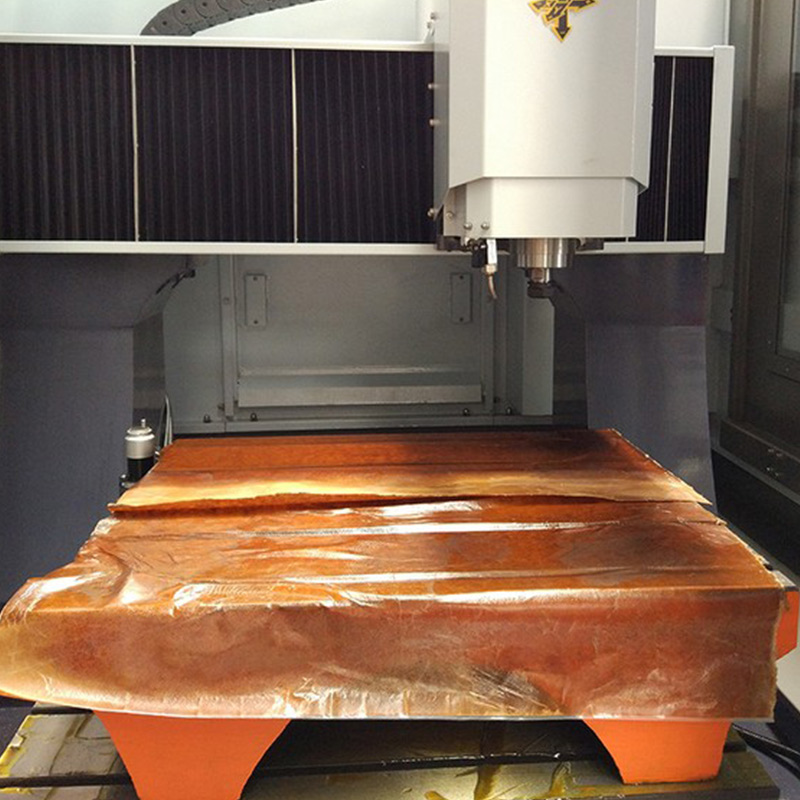

The CNC engraving and milling machine DC6050A for copper electrodes is designed for precision engraving and milling. It excels at making precision aluminum molds, metal products, and even precision steel engraving.

1. High-precision CNC special bearings

2. High-precision guide rails and ball screws

3. Imported servo motor to ensure high rigidity and processing accuracy of the machine tool

4. 3KW high-precision variable frequency electric spindle

5. Suitable for processing precision drop-molding molds, hot stamping molds, copper electrodes, injection molds, cold stamping molds, steel molds

1. Precision aluminum mold production

2. Metal product manufacturing

3. Precision steel engraving and milling