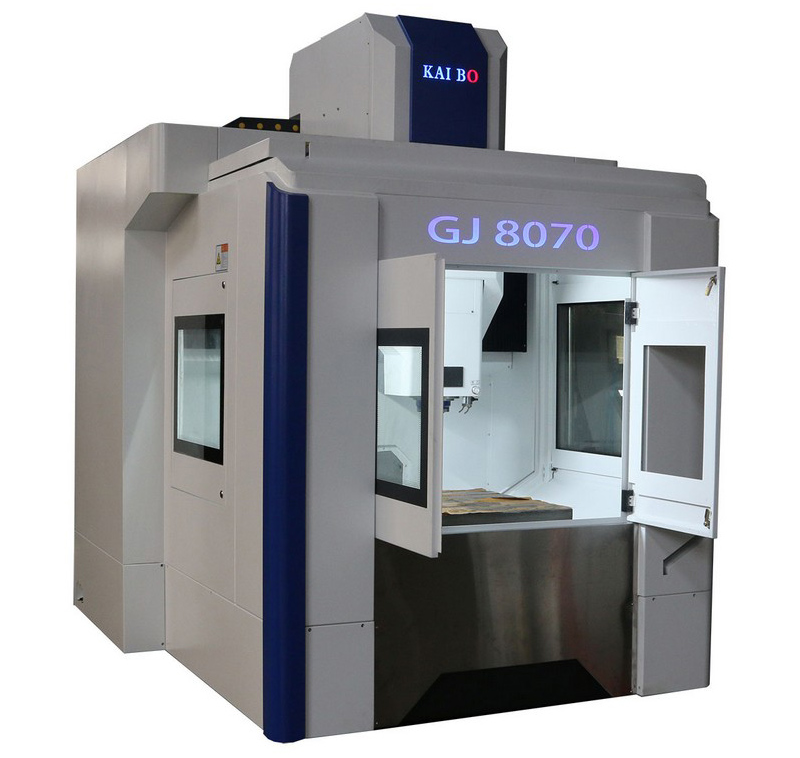

The high-precision and high-speed CNC milling machine GJ8070 is a double-column high-speed vertical machining center. It is equipped with a Fanuc control system and an HSK high-speed spindle, suitable for high-precision molds and fine surface finishing processes.

1. Fanuc control system, reliable operation.

2. HSK high-speed spindle can achieve high-precision processing.

3. Combine lighter milling processes with higher spindle speeds and higher feed rates.

4. The spindle speed is up to 30000 rpm, which can improve productivity.

5. All guide rails are linear guide rails to enhance rigidity and precision.

6. Reduce cycle time, increase tool life and shop productivity.

1. The mold manufacturing is of high precision.

2. Fine surface treatment technology.

3. Graphite processing.

4. Roller processing.

5. Plastic mold.

6. Shoe model.

7. Automobile parts processing.

8. Hardware processing.