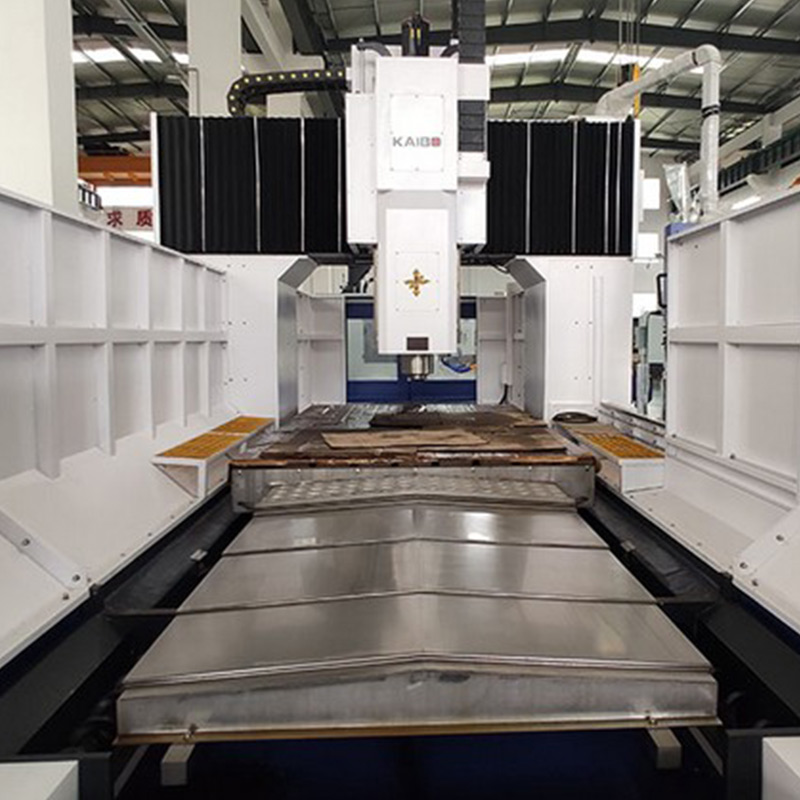

The double-column large CNC milling machine GV1625 is designed for complex large parts machining, such as fuselage components, layup molds and composite structures. The machine's rigid steel structure provides a very stable cutting platform.

1. Double-column heavy-duty milling machine ensures stable and precise operation.

2. Designed for complex and large parts processing, suitable for a variety of applications.

3. Rigid steel structure provides a very stable cutting platform.

4. Mobile protective devices ensure operator safety and cleanliness of the workplace.

5. Equipped with high pressure coolant (HPC) to improve chip evacuation and reduce the need for pecking.

6. The X-axis uses three linear guides to optimize dynamic characteristics.

7. The Z axis adopts four linear guides to improve the machine life and accuracy.

8. The Z axis adopts double ball screw and pneumatic balance system to achieve high-speed cutting.

9. Customizable 3/4/5-axis technology options.

1. Processing of fuselage parts

2. Lay-up molds and composite structures

3. Plastic mold

4. Shoe Model

5. Auto parts

6. Graphite and roller processing