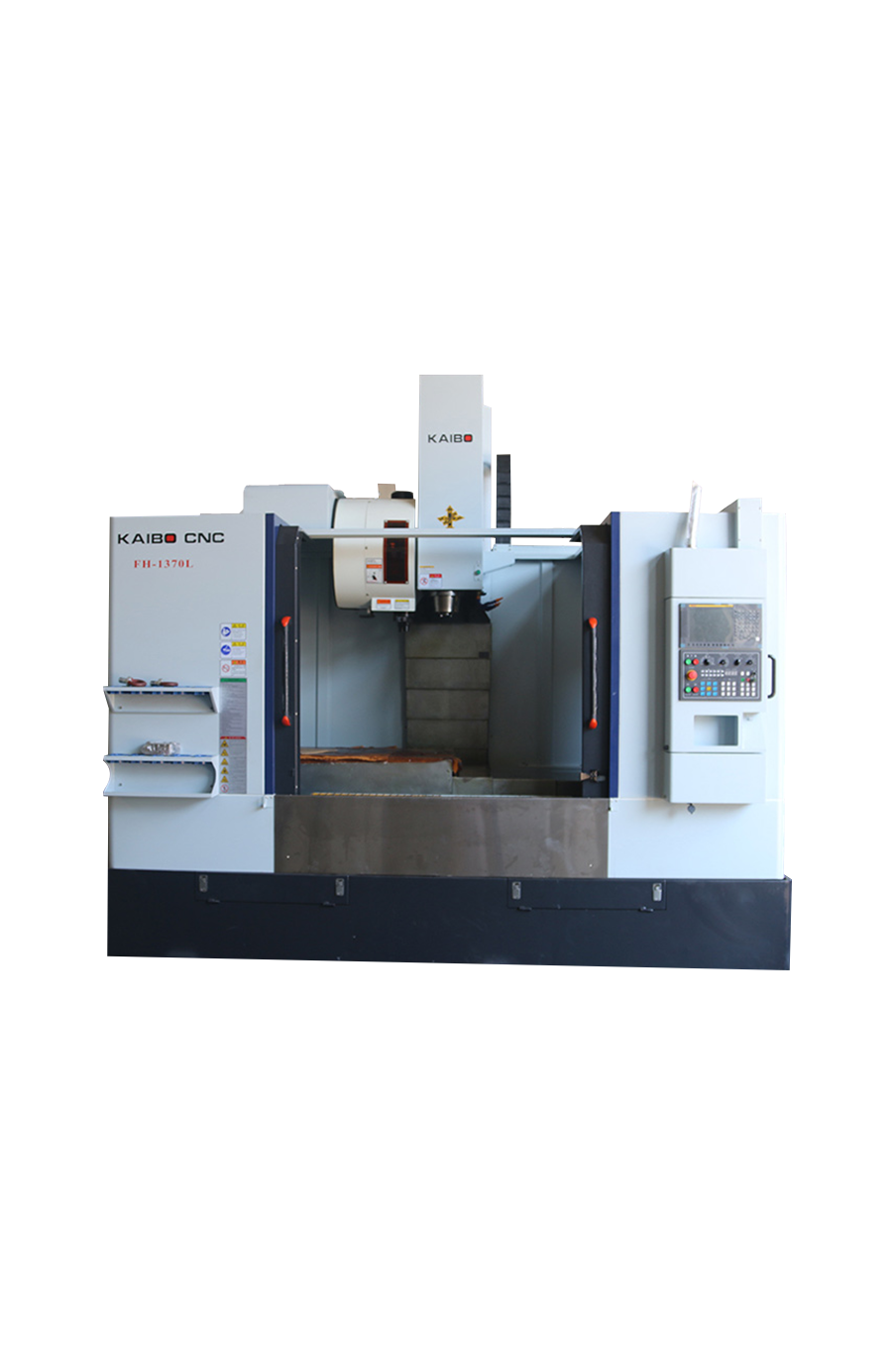

In the realm of die manufacturing, high-precision milling machines play a pivotal role. These sophisticated tools not only enhance productivity but also ensure the utmost accuracy in the production process. The integration of cutting-edge CNC technology allows manufacturers to achieve intricate designs that meet the exacting standards of today’s tooling industry.

High-precision milling machines bring numerous advantages to die manufacturing. These include reduced machining time, lower material wastage, and the ability to produce complex geometries. As a result, manufacturers can achieve a remarkable return on investment while delivering products of superior quality.

The applications of high-precision milling machines extend far beyond traditional die manufacturing. They are utilized in various sectors such as automotive, aerospace, and electronics, where precision is paramount. Continuous technological innovations ensure that these machines remain at the forefront of efficiency and capability.

In conclusion, the landscape of die manufacturing is transformed with the advent of high-precision milling machines. By leveraging these tools, manufacturers are able to push the boundaries of what is possible, driving innovation and excellence in the tooling industry. The future is bright, and I am excited to witness the ongoing evolution driven by these remarkable machines.