As the leader of the marketing team, I have witnessed the remarkable evolution of CNC technology, particularly the role of harmonic gear designs. These innovations significantly improve the operational efficiency and accuracy of machines like the DC6060A 5-Axis CNC Milling Machine. In this article, I'll delve into the advantages of these designs and their importance in modern manufacturing processes.

The harmonic gear design offers a significant reduction in backlash, resulting in increased precision during machining operations. This translates to higher quality finished products and less rework, ultimately improving operational efficiency in manufacturing.

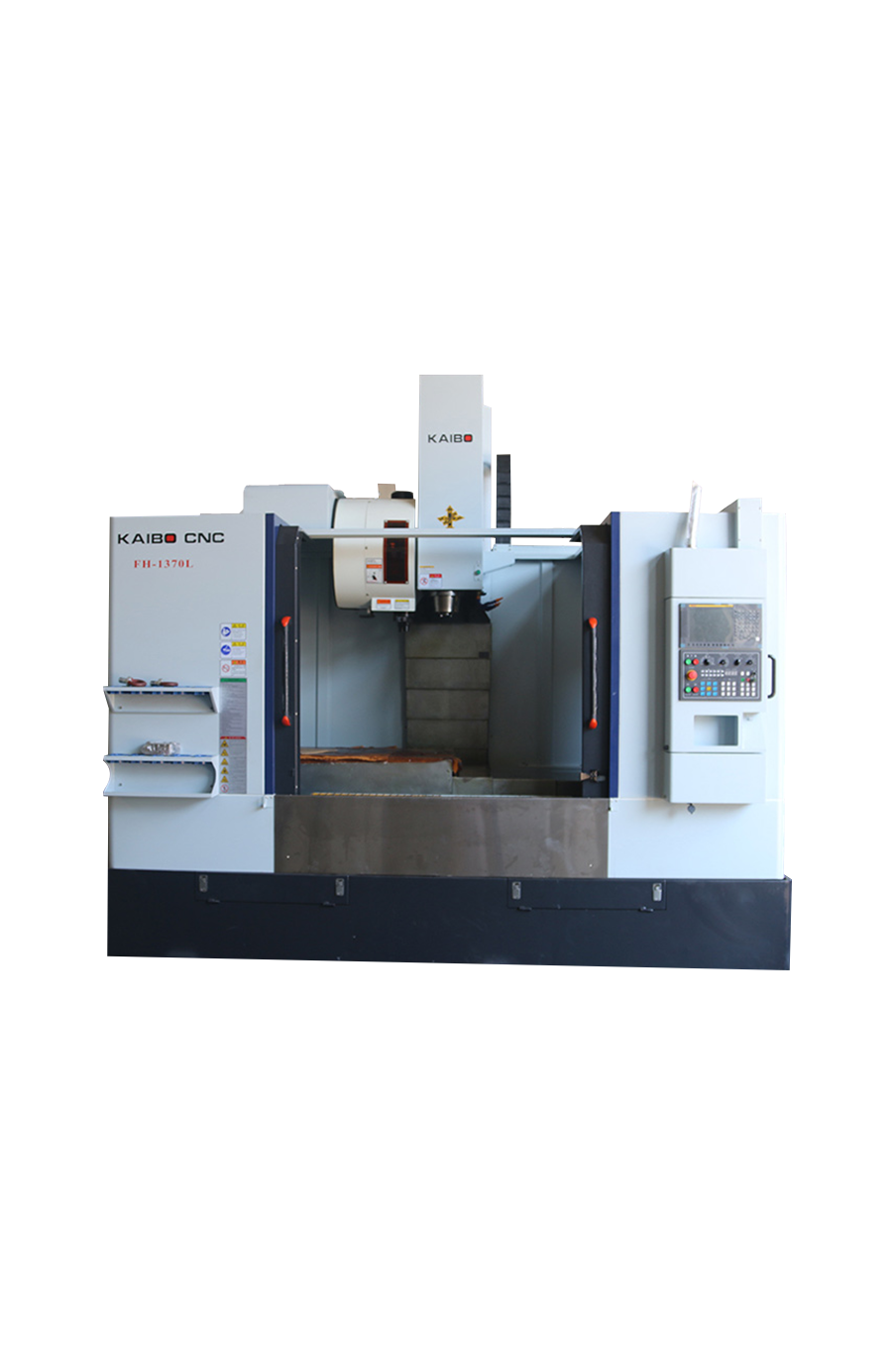

The compact nature of harmonic gears allows for more space-efficient designs in machinery. The DC6060A, benefiting from this technology, presents an optimal footprint without compromising performance, making it suitable for various manufacturing environments.

Harmonic gear technology is prevalent in various applications, from aerospace to automotive manufacturing. The DC6060A's capability to handle complex tasks with ease demonstrates the broader applicability of harmonic designs, which enable manufacturers to tackle intricate projects efficiently.

In summary, the advantages of harmonic gear design in the DC6060A 5-Axis CNC Milling Machine are undeniable. By enhancing performance, enabling compact construction, and broadening applicability, this technology is pivotal in advancing the manufacturing industry.